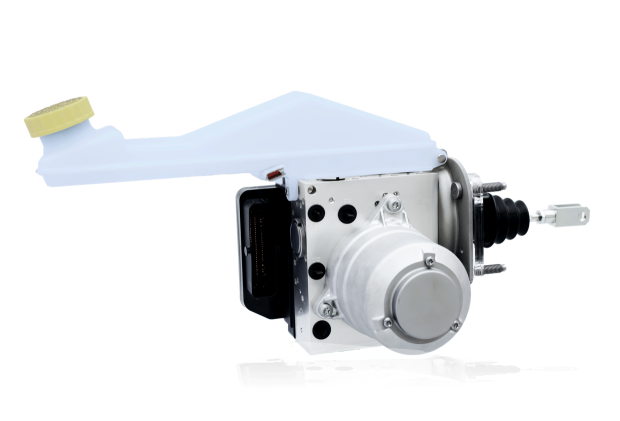

Intelligent braking system

In 2021, the product was designated as an "Advanced Technical Product in the Key Fields of Jiangsu's Automobile Industry" and was included in the Catalogue of Major Innovative Technologies and Products of Key New Energy Vehicle (NEV) Enterprises in Jiangsu Province (2021)

The project was included in the 2021 Nanjing "Zijin Zhidian" Industry Chain Technology Tackling Projects

Redundant safety system

Three-level redundant architecture design (IBC main module + RBU redundant module + distributive EPB); functional safety could reach ASIL Level D to meet the requirements of high-level automatic driving; switching speed of master/redundant system ≤100ms

Efficient lightweight assembly

The mechanical transmission efficiency of a coaxial brushless motor direct drive transmission mechanism could attain ≥86%; design of integrated lightweight electromechanical and hydraulic coupling mechanism; high-precision linear solenoid valve

Agile and reliable electric control

Low power consumption: The system’s current under the sleep node is less than 200μA, allowing for ultra-long vehicle standby time; minimal latency: High-speed sensor signal processing, with a CPU frequency of 300M, contributes to faster signal transmission and data processing; high reliability: The system power-off protection circuit, segmented big capacitor pre-charging, and three-rail redundant power supply system are the best ways to ensure safety

Mainstream robust algorithm

Meet the requirements of the Autosar architecture, ASPICE specification, and functional safety development process; strategy for multi-core heterogeneous lockstep software tasks; motor processing technique with three-loop coordinated control and noise reduction; Solenoid valve flow matching and linear control technology

*

Technical Parameters of Product

| Main parameters | |

| Technical indexes | Indexes |

| Weight (kg) | <5.8 |

| Dynamic build-up time (ms) | ≤140 |

| Fluid replacement performance (ms) | ≤200 |

| Max. pressure build-up capacity (bar) | ≥200 |

| Quick release time (s) | ≤0.3 |

| Steady-state regulation accuracy (bar) | <1 |

| Noise NVH (dB) | ≤68dB@ABS、≤50dB@ACC |

| Life (10,000 times) | ≥220 |

| Interface specification | |

| Interface name | Specification |

| Brake pedal ratio | ≥3.3 |

| Waterproof and dustproof | Meet IP6K9K |

| Hydraulic circuit type | Type "X" or "H" (optional) |

| Pedal connector | Pusher fork or pusher ball (optional) |

| Overall dimensions of IBC assembly | 176.5*188*161.5mm (excluding oil pot) |

| Firewall interface size | Threaded link 72*72mm or 80*60mm (adjustment based on model supported) |

| Brake pipe | Comply with ISO4038, M10*1.0, and M12*1.0 (adjustment based on model supported) |

| ECU connector | Comply with standard JA3724-HL-1 (adjustment based on model supported) |

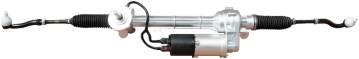

Redundant intelligent steering

Mechatronics integration system design

Electric drive integration technology, high torque and power output, and system architectural redundancy design

Algorithms for complete kernel and advanced function control

Intelligent driving functions such as automatic parking/lane change assist/lane maintaining, and advanced functions such as off-tracking compensation/vibration suppression/friction compensation, etc.

Motor compensation algorithm for basic control such as assist control/yaw damping/active return, and torque fluctuation suppression Redundant permanent magnet synchronous motor drive and control and diagnosis, complex motor 6-phase current reconstruction technology, etc.

Motor compensation algorithm for basic control such as assist control/yaw damping/active return, and torque fluctuation suppression Redundant permanent magnet synchronous motor drive and control and diagnosis, complex motor 6-phase current reconstruction technology, etc.

Intelligent networking support design

Comply with information security needs, and support OTA upgrade technology and cloud deployment monitoring

Comply with function safety design

When assistance (sLOA) is unexpectedly lost, the electronic control system can fulfill ASIL D functional safety level

Double-pinion redundant intelligent steering system RISS-dp

Double-pinion redundant intelligent steering system RISS-dp Electric drive unit RPK-dp of pinion redundant intelligent steering system

Electric drive unit RPK-dp of pinion redundant intelligent steering system Rack-type redundant intelligent steering system RISS-r

Rack-type redundant intelligent steering system RISS-r Electric drive unit RPK-r of the rack-type redundant intelligent steering system

Electric drive unit RPK-r of the rack-type redundant intelligent steering system

*

Technical Parameters of Product

| Content of technical characteristics | RISS-r | RISS-dp |

| Motor type | 6-phase permanent magnet synchronous motor | 6-phase permanent magnet synchronous motor |

| Phase current peak of electric control system (A) | 200 | 160 |

| Max. rack force (kN) | 16.5 | 12.5 |

| Sensor Type | TAS 4+2 | TAS 4+2 |

| RPK dustproof and waterproof | IP6K9K | IP6K9K |

| sLOA failure rate | < FIT10 | |

| Fault tolerance time(ms) | <25 | <25 |

| Active alignment residual angle (°) | <1.5 | <1.5 |

| Torque fluctuation(Nm) | <0.2 | <0.2 |

| Single-point time-dependent diagnostic coverage | >99 | >99 |

| Execution angle error(°) | Min(5%*Angle req,1.5) | Min(5%*Angle req,1.5) |